Due to the numerous influencing factors, the injection pressure curve is characteristic for the respective application – and therefore unique.

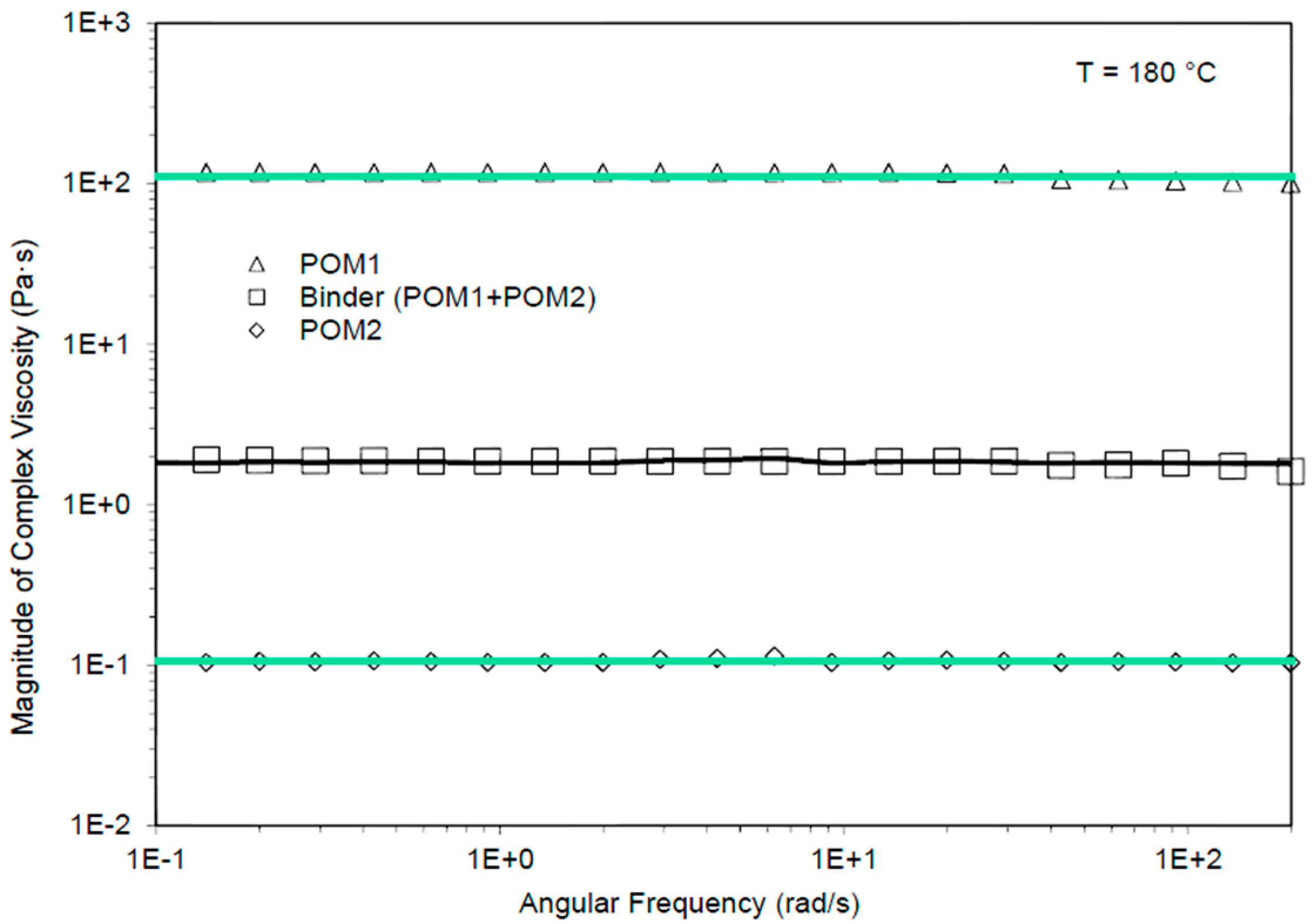

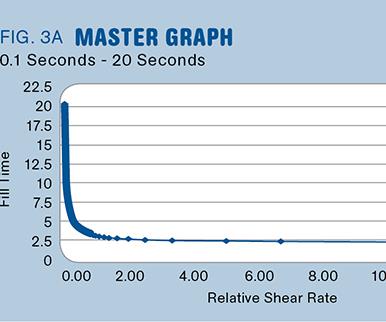

From this data, the machine control system calculates set-point pre-set values, which the injection controller fulfils as closely as possible.Īpart from injection speed, the resulting pressure curve depends on the amount of melt, the material's flowability, and the flow resistance. The machine operator enters set-points for starting position, speed profile, and a switchover point for the screw movement in the speed-controlled filling phase. While developing the software, particular attention was payed to cavity filling. Integrated into the machine control, they even enable manufacturing processes to continuously optimise themselves – a feature that will be standard in the factory of the future! The software iQ weight monitor from Engel provides plastics processors with data informing them for which processes the investment in additional assistant systems is worthwhile. Taking these factors into account, intelligent assistant systems are developed. However, it must be noted that these sensors are located further away from the actual processing location than sensors in the mould. For example, the signals from sensors used for the control and sequencing of machine movements, also permit conclusions about component quality to be drawn. Hereby, it is most effective to use signals that are provided anyway by the sensors in the machine. If such variations are detected and compensated early enough during ongoing production, process efficiency can be improved. In spite of repeatable machine movements, the quality of the produced components can be subject to certain variations, caused by changes in ambient conditions or the material properties, for example. One decisive success factor for the efficiency of injection moulding processes is a low reject rate. Intelligent assistant systems enable plastics processors to generate parameters that are relevant for component quality: injected volume, melt viscosity variation, and pressure deviations during injection. In the past, attention was focused on axis movements and the associated necessary forces and times. The machine control enables the injection moulding process to be monitored effectively by means of quality-relevant process parametersĬyclically measured process parameters are used for monitoring and optimising injection moulding processes.

0 kommentar(er)

0 kommentar(er)